< Previous | Contents | Next >

Section 3 Welding Works and Inspection

303. Application of welding consumables

Hydrogen cracking test specified in 303. (4) of the Rules is to comply with K S B ISO 17642-2 or equivalent.

304. Preparation for Welding

1. Tack welding

(1) The application to 304. 2. (3) of the Rules is to be in accordance with the followings:

(A) The bead length of tack welds is to comply with Table 2.2.2 of the Guidance.

![]()

![]()

![]()

Table 2.2.2 Bead length of tack welds

Steel grade | Kinds | Required Bead length | Remark |

Higher strength- low alloy steel Steel casting | Ceq>0.36% | 50 mm | including TMCP |

Ceq 0.36% | 30 mm | ||

grade E mild steel | 30 mm |

![]()

(B) The pitch of tack welds should generally be approximately 400 mm or shorter.

305. Welding sequence and direction of welding

1. "The special approval of the Society" specified in 305. 3 of the Rules means the fillet weld to satisfy the following.

(1) The welding procedure qualification tests specified in successful.

(2) The welding consumables are to be those for welding

proved by the Society.

Sec. 4 of the Rules are accepted as with direction of vertical-downward ap-

(3) The joints of steels which welding with direction of vertical- downward is restricted, in general,

is to comply with Table 2.2.3-1 of the Guidance.

Table 2.2.3-1 Joints of Steels which Welding with Direction of Vertical Downward is restricted

Grade of steels | Welded joints |

Rolled steels for hull | Joints of any E grade to any E grade(E, EH32 and EH36) |

Rolled steels for low temperature services | Joints of any steels for low temperature service to any steels for low temperature service, Joints of any steels for low temperature service to any grade of steels |

High Strength Quenched and Tempered Steels for Welded Structures | Joints of any high strength quenched and tempered steels to any high strength quenched and tempered steels, Joints of any high strength quenched and tempered steels to any grade of steels |

Stainless clad steel plates | Joints of any stainless clad steel plates to any stainless clad steel plates, Joints of any stainless clad steel plates to any grade of steels |

Rolled stainless steels | Joints of any rolled stainless steels to any rolled stainless steels, Joints of any rolled stainless steels to any grade of steels |

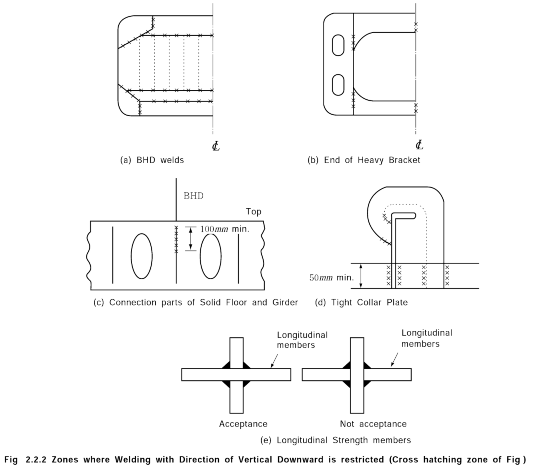

(4) The zones where welding with direction of vertical- downward is restricted to hull structure, in general, is to comply with Table 2.2.3-2 of the Guidance.

2. Notwithstanding the provisions of 1 (3) and (4), the other plans presented by shipbuilder or manu- facturer may be accepted provided that the quality control system of shipbuilder and the importance of the welds are considered and deemed appropriate by the Society.

![]()

28 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

![]()

Table 2.2.3-2 Zones where Welding with Direction of Vertical Downward is restricted

Divisions | Locations and members |

Fillet welded joints of primary strength member | - The welds of BHD(See Fig 2.2.2, (a) of the Guidance) - Cross hatching areas of Fig 2.2.2, (c) of the Guidance within connection areas of solid floor and girder - Connection areas of primary strength member and bottom shell, side shell, up- per deck and double bottom tank top |

Areas where water, oil and air tightness are required | - Boundary line where water, oil and air tightness are required - The area whose distance from the end of tight collar plate shall be at least 50 (See Fig 2.2.2, (d) of the Guidance) |

Areas where structural con- tinuity is required or where high concentrated stress is ex- pected | - The end of heavy bracket (See Fig 2.2.2, (b) of the Guidance) - Longitudinal strength members (See Fig 2.2.2, (e) of the Guidance) |

Areas where high concentrated loads is expected | - The lower part of crane post - The lower part of crane pedestal |

Specified areas | - The lower part of main engine : Connection areas of main engine girder and follr - Hatch cover : Connection area of side plate and end plate - Hatch coaming : Connection areas of main plate and top plate, Connection areas of main plate main plate - Shaft bed - Rudder horn : Connection areas of casting steels and normal strength steels - Rudder : Connection areas of rudder main pieces and rudder stocks, Connection areas of casting forging steels and normal strength steels - Bracket toe |

(Note) Harmful defects such as cracks may, if necessary, be inspected by magnetic particle inspection or liquid pene- trant inspection and, where the condition of the quality is serious, the welding work is to discontinue until measures for importance are planned. | |

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 29

![]()

306. Main welding

1. In application of 306. 2 of the Rules, minimum preheating temperature for welding hull steels at low temperature is to comply with Table 2.2.4 of the Guidance.

![]()

Table 2.2.4 Preheating for Welding Hull Steels at Low Temperature

Grades | Standard | ||||||

Base metal temperature needed preheating | Minimum preheating temperature | ||||||

Normal strength steels (A, | B, | D , | E) | below 0 | 20 | or over | (1) |

Higher strength steels (AH 32, D H 32, EH 32, AH 36, D H 36, EH 36) | |||||||

Note : (1) This level of preheat is to be applied unless the approved welding procedure specifies a higher level | |||||||

2. "The welding inserting a liner of suitable size" in 306. 8 of the Rules complies with the Fig

2.2.3 of the Guidance.

![]()

30 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

3. In application to 306. 9 of the Rules, the term "special approval of the Society" means the accept- ance in accordance with Pt 1, Ch 1, 104. or 105. of the Guidance.

309. Quality of welds

In 309. 3 of the Rules, the application to the non-destructive inspection specified elsewhere is to comply with Annex 2-7.

311. Welding works for YP47 Steel Plates

1. Welder

Welders engaged in YP47 welding work are to possess welder’s qualifications specified in Pt 2, Ch 2, Sec 5 of the Rule.

2. Short bead

Short bead length for tack and repairs of welds by welding are not to be less than 50mm. In the case where ![]() is less than or equal to 0.19, 25mm of short bead length may be adopted with approval of the Society.

is less than or equal to 0.19, 25mm of short bead length may be adopted with approval of the Society.

3. Preheating

Preheating is to be 50°C or over when air temperature is 5°C or below. In the case where ![]() is less than or equal to 0.19, air temperature of 0°C or below may be adopted with approval of the Society.

is less than or equal to 0.19, air temperature of 0°C or below may be adopted with approval of the Society.

4. Welding consumable

(1) Specifications of welding consumables for YP47 steel plates are to be in accordance with

Table 2.2.5

![]()

Table 2.2.5 Mechanical properties for deposited metal tests for welding consumables

Mechanical Properties | Impact test | |||

Yield Strength ( | Tensile Strength ( ) | Elongation (%) min. | Test Temp. (°C) | Average Impact Energy (J) min. |

460 | 570~720 | 19 | -20 | 53 |

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 31

![]()

(2) Consumable tests for butt weld assemblies are to be in accordance with Table 2.2.6.

![]()

![]()

Table 2.2.6 Mechanical properties for butt weld tests for welding consumables

Tensile strength ( ) | Bend test ratio: ( ) | Charpy V-notch impact tests | ||

Test temp (°C) | Average energy (J) min. | |||

Downhand, horizontal-vertical, overhead | Vertical (upward and downward) | |||

570~720 | 4 | - 20 | 53 | 53 |

5. Others

(1) Special care is to be paid to the final welding so that harmful defects do not remain.

(2) Jig mountings are to be completely removed with no defects in general, otherwise the treatment

of the mounting is to be accepted by the Society.

![]()

32 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()